RTTY TAPE EQUIPMENT

and

TRANSMITTER DISTRIBUTERS (TD)

In reponse to many inquiries, RTTY, with permission from the

TELETYPE CORPORATION, presents this material to assist the newer

RTTYers to know what some of the others are talking about.

There are as many reasons for wanting tape gear as there are

amateurs. It provides the most rapid means of handling traffic on

amateur frequencies. It is accurate, reliable, and fast. It also

provides a means of preparing an answer while receiving another

station. This makes even the slowest typist sound like an

"old-timer". Also it can be used for bulletins of

general interest, such as the ARRL broadcast from W1AW's copy.

Equipment lists of your station (BRAG TAPES), Hi. For MARS net

and RACES net operations it can be used very effectively. Net

rosters, net call ups and so on. Its limitations are those of the

operator. Many circuits to enable cutting type from "local

loops" and from the TU have been printed in RTTY.

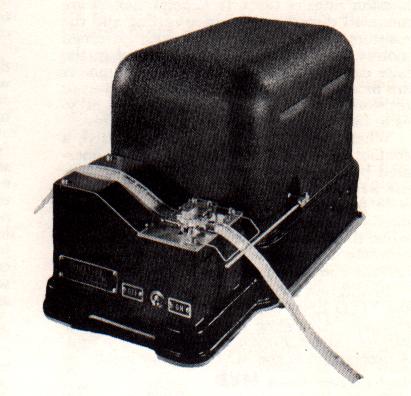

Tape equipment, like many other items, comes in many forms.

Fig. 1 shows the popular Model 14 Transmitter-Distributor (L4TD).

Teletype's description is given below.

DESCRIPTION OF THE TRANSMITTER DISTRIBUTOR

General

The transmitter distributor is a motor driven device

which translates code combinations, perforated in a paper tape,

into electrical impulses and transmits these impulses to one or

more receiving stations. The tape may he perforated by any one of

several models of Teletype perforating or reperforating machines.

There are two kinds of transmitter distributors; one for

transmitting five unit code, and the other for transmitting six

unit code. These two kinds are identical except that the six unit

code machine accommodates a wider tape and provides for the

transmission of an additional impulse. The following description

pertains specifically to the five unit transmitter distributor.

NOTE: In all the figures of this bulletin, end views of fixed

pivot points are designated by solid black circles.

Theoretical Transmitting Circuits

The portion of the unit through which the perforated

tape feeds is known as the transmitter The transmitter prepares

electrical paths from the signal line battery to the commutator

segments of the distributor. These paths are controlled by tape

pins which sense the perforations in the tape and thereby

determine the positions of the contact tongues with relation to

their upper and lower contact screws.

The distributor completes the connections to the signal line.

Connections are made in sequence at a constant rate of speed by

brushes which traverse the segments and the collector ring.

The Tape Sensing Mechanism

The contact levers are positioned vertically in the

transmitter. They pivot on a shaft S and have extensions to the

right C, left A, and downward B. The right-hand extensions

project upward at the ends and have tape pins embedded in them.

An opening is provided in a tape guide, located above the

right-hand extensions of the contact levers, to permit the tape

pins to enter the code holes in the tape. The left-hand extension

of each contact lever carries a contact tongue which is attached

to the contact lever by a pivotal mounting. Each contact tongue

is positioned to move between two contact screws, a spacing

contact screw above, and a marking contact screw below. A contact

lever spring is attached to the mounting end of each contact and

tends to hold it against the lower contact screw. A contact lever

bail, pivotally mounted just below contact lever lower

extensions, has an arm extending downward engaging a transmitter

operating lever. This transmitter operating lever has a central

pivot screw and moves in a horizontal plane. A roller on the rear

end of the lever rides a transmitter operating cam mounted on the

lower end of the distributor shaft. The motion imparted to the

transmitter operating lever by the operating cam causes the

contact lever bail to rotate the contact levers on their shafts

sufficiently to move the contact tongues up and down between the

marking and spacing contact screws. After the tongues strike the

upper screws, any additional clockwise rotation of the contact

levers is absorbed by the contact lever springs. When the

distributor brush comes to rest on the stop segment the

transmitter operating lever roller is on the peak of its cam,

thereby holding the tongues against the spacing contacts and also

holding the tape pins, located in the right-band extensions of

the contact levers, below the holes in the tape. As the

transmitter operating lever roller rides to the low part of its

cam, the tape pins rise. If tape perforated with code

combinations is in the tape guide at this time, the contact lever

pins will project through the tape wherever the tape is

perforated and permit the associated contact tongues to rest on

the marking contacts, while the pins will he blocked at the

unperforated portions and the associated contact tongues will he

held against the spacing contacts. The tape will be held

stationary and the contact tongues will maintain their positions

as determined by the code perforations while the distributor

brush is traversing segments one to five inclusive. The inner

distributor brush will transmit marking impulses to the line from

segments associated with tongues that rest on the lower contacts,

and spacing impulses (for polar signal transmission) from

segments associated with tongues that are on the upper contacts.

When "make-break" signal transmission is used (battery

applied only to the lower contacts), a no-current interval occurs

when the contact tongues are against the spacing contacts.

The Distributor Mechanism

The distributor is made up of two concentric conducting

rings mounted on a fiber disc. The outer ring is divided into

seven segments. Segments Nos. 1 to 5, inclusive, correspond to

the five intelligence intervals of the five unit code and are

connected to the five contact tongues

Immediately preceding No. 1 segment is the start segment. The

segment following No. 5 segment is the stop segment. The stop

segment and the lower contact screws are permanently connected to

marking line battery. The start segment and the upper contact

screws are connected to spacing line battery only when it is

desired to transmit polar signals; otherwise, the upper contact

screws and the start segment have no battery connections. When

the distributor brush passes over the start segment, a spacing

impulse is always transmitted, whereas a marking impulse always

results when the brush traverses the stop segment. These two

invariable impulses cause the receiving mechanism to operate in

unison with the distributor brush arm.

Tape Feeding Mechanism

Positioned to the rear of the contact levers and pivoted

on the contact lever shaft is a feed lever which is similar in

shape to a contact lever. The feed lever has a spring attached to

its left-hand extension and a feed pawl mounted on its right-hand

extension C. A feed pawl spring holds the feed pawl in contact

with a feed wheel ratchet. Pins on the circumference of the feed

wheel project through an opening in the tape guide and mesh with

the feed holes in the tape. A retaining lid, under which the tape

passes, holds the tape in contact with the feed wheel pins. When

the action of the contact lever bail on the contact lever moves

the tape pins downward, the feed lever responds in a similar

manner, causing the feed pawl to engage a tooth on the feed wheel

ratchet and rotate the feed wheel. With each downward motion of

the feed pawl, the tape will be advanced from right to left, the

distance required to bring the succeeding code combination over

the tape pins. The setting of the feed pawl is such that it does

not start to rotate the feed wheel until the tape pins have moved

clear of the tape. A feed wheel detent is provided to insure

alignment of the code perforations with the tape pins. The

position of the operating cam with relation to the distributor

brush is such that the contact tongues are not moved from the

lower contacts until after the brush has reached the stop

segment. While the brush is passing over the stop segment, the

tape is advanced.

Starting and Stepping Transmission

The main shaft is driven by a motor through the medium

of gears and a friction clutch. When the motor is running,

transmission is stopped by blocking the rotation of the main

shaft and started by unblocking it. This is done through the

medium of a stop arm which is under the control of a tape stop

magnet and a sprint. The magnet, when energized, holds the stop

arm clear of the lug. The spring holds the stop arm in the path

of the lug when the magnet is de-energized. The circuit to the

magnet may be opened or closed by means of the tight-tape stop

contacts, tape stop switch, or the end-of-tape stop mechanism

contacts which are described in the three paragraphs that follow.

Tight-Tape Stop Mechanism (Auto-Stop Mechanism)

When the slack in the tape between the tape perforator

and the transmitter is taken up, the tape raises the tight-tape

stop lever which opens the circuit to the tape stop magnet

allowing the stop arm to engage the lug on the stop cam. A tape

guide wire may also be employed to guide slack tape within close

proximity of the tight-tape stop lever so as to raise the lever

and stop transmission if the tape feeding into the transmitter

becomes tangled, thus preventing mutilation of the tape feed

wheel perforations.

Tape Stop Switch

Transmission can also be stopped by manually operating

the tape stop switch. This switch controls the release magnet in

a manner similar to that of the mechanism described in the

preceding paragraph.

NOTE: On some types of distributors, this switch is connected

in the motor circuit and is then used to start or stop the motor.

End-of-Tape Stop Mechanism

Another means may be provided for automatically stopping

transmission when a length of tape has passed through the

transmitter. This is accomplished by another pair of contacts

located beneath the tape guide which are operated by a pin that

projects through the tape guide When the tape retaining lid is

closed, the end-of-tape stop pin is depressed and the contacts

are held closed so long as there is tape between the pin and the

lid. When the end of the tape passes the pin, the tension of the

contact spring raises the pin and opens the contacts, stopping

transmission.

Synchronous and Governed Motors

Where regulated A.C. power is available, a synchronous

motor maybe used, otherwise governed motors must be used.

Governed motors are available for operation on either A.C. or

D.C. The speed is controlled by a centrifugal contact mechanism

having commutator rings or discs. In general, motors are mounted

directly to the base casting and the resistors and condenser used

with governed motors are mounted on the base and in the base

cavity. However, some governed motors are mounted to a base plate

having governor resistors and a condenser mounted on it so as to

form a complete motor unit assembly.

When an A.C. governed motor is used, a contact assembly is

provided which is operated by the tape stop magnet stop arm

(figure 9). The purpose of the contact assembly is to provide

better speed control by introducing a resistor in series with the

motor when the distributor shaft is rotating, and by shunting the

resistor when the load of the friction clutch is added to the

motor.

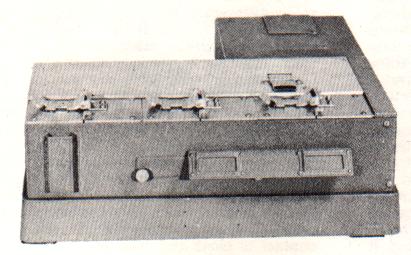

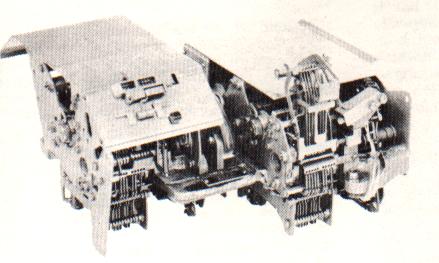

In addition to the 14TD, many versions of the MXD

have been issued through MARS channels. Also some have been found

on the surplus market. Figure 2 shows one such unit. A

description of the MXD is given below. In addition to the 14TD, many versions of the MXD

have been issued through MARS channels. Also some have been found

on the surplus market. Figure 2 shows one such unit. A

description of the MXD is given below.

Multiplex Transmitter Distributor (MXD)

The multiple transmitter distributor set is a mechanism

which, when used in combination with reperforators, provides

combined sending and receiving facilities for tape message

relaying. A complete set consists of three multiple transmitter

distributor units and a motor unit mounted on a base which is

equipped with cross shaft, gears and terminal strips. Two of

these units are message transmitters and the third is a number

transmitter. The function of the number transmitter is to insert

automatically into the signal line successive numbers, from a

number tape, which will identify each message before it is

transmitted. The number transmitter is like the message

transmitter except that it is equipped with a letter sensing

mechanism which makes it responsive to the letters combination in

the number tape causing stoppage of the number transmitter and

starting of a message transmitter through external electrical

control circuits.

The multiple transmitter distributors (message or number

transmitters) are arranged to handle either perforated or

chadless tape received from other stations on reperforators, or

prepared locally on keyboard perforators.

The message transmitter consists essentially of the following

mechanisms: a 7.42 unit code transmitting cam cylinder with

associated transmitting contacts, a tape feed and tape sensing

mechanism, a hinged tape lid, an automatic tape out control

feature, a manual control mechanism, a magnet operated clutch, a

driven gear, and a transmitting contacts filter. (See figures 3

and 4.) This unit is geared for transmission at the speed of

368.1 o.p.m.

The transmitting cam cylinder is normally held stationary

because the clutch members on the transmitting shaft are held

disengaged by the clutch throwout lever. When the clutch magnets

are energized, the clutch members engage and the rotation of the

transmitting cam cylinder begins the cycle of operation.

The transfer of the code combination in the perforated tape to

the contact levers which control the transmitting contacts is

accomplished by means of the selector lever bail, its cam,

selector pins and selector levers.

The selector lever bail extension roller rises from

the indent on its cam and causes the selector lever bail to move

away from the selector levers. The selector lever springs pull

the selector levers up toward the tape. The selector p ins which

encounter perforated holes in their path advance through the

perforations, but the pins which do not encounter perforations as

they come in contact with the tape, are blocked by the tape and

are prevented from advancing farther. The selector lever bail extension roller rises from

the indent on its cam and causes the selector lever bail to move

away from the selector levers. The selector lever springs pull

the selector levers up toward the tape. The selector p ins which

encounter perforated holes in their path advance through the

perforations, but the pins which do not encounter perforations as

they come in contact with the tape, are blocked by the tape and

are prevented from advancing farther.

Each selector lever is positioned through the medium of the

perforations in the tape, to correspond with each signal impulse

to be transmitted. Each selector lever controls the motion of a

contact lever either by allowing the contact lever to close its

contact when the cams revolve, or by restricting the motion of

the contact lever. If the selector pin does not enter a

perforation in the tape, corresponding to a spacing impulse, the

lower end of the selector lever engages the associated contact

lever and prevents it from rising into an indent of the cam, as

the cam rotates, thus holding the circuit open for that impulse.

If the selector pin enters a perforation in the tape,

corresponding to a marking impulse, it does not interfere with

the movement of the contact lever. Then, as the cam revolves, the

contact lever rides on the cam periphery and drops into an

indent, thereby allowing its contact to close and send out a

marking impulse. As the cams rotate, the impulses, either marking

or spacing, are transmitted in succession.

The start-stop cam controls a contact lever which, in turn,

actuates the start-stop contacts. These contacts are opened at

the beginning of each revolution of the cam cylinder to transmit

the start impulse (spacing) and remain open during the

transmission of the five impulses. After the fifth impulse has

been transmitted, the start-stop contacts again close, sending

the stop impulse (marking) to the line.

After the fifth impulse has been transmitted, the selector

lever bail extension drops into the indent in its cam causing the

selector lever bail to retract all the selector levers from their

sensing position. At this moment the feed pawl arm roller drops

into the indent in its cam and the feed pawl engages the feed

wheel ratchet, stepping it forward, thereby advancing the tape

one character space over the selector p ins. A feed wheel detent

establishes the relative setting of the feed wheel.

The transmitting cam-cylinder rotates continuously as long as

the clutch magnets are energized. An interruption of the clutch

magnet circuit causes the clutch throwout lever to engage the

cammed surface of the driven member of the clutch due to the

action of the clutch throwout lever spring and, as the

transmitting shaft rotates, the driven clutch member is cammed

out of mesh with the driving member.

Within the unit there are two provisions for interrupting the

clutch magnet circuit. The clutch magnets are connected in series

with a set of automatically operated contacts and a set of

manually operated contacts. The opening of either set of contacts

stops the unit.

- AUTOMATICALLY OPERATED TAPE-OUT CONTACTS

- The automatic contacts are a function of the tape-out

feature. The unit has a tape-out sensing lever which

operates in unison with the other five selector levers.

The associated sensing pin is in line with and adjacent

to the sensing pin f or the first impulse. It has a

larger sensing area and a portion of it senses along the

edge of the tape during the transmission of each

character. When the end of the tape has passed through

the transmitter the tape-out sensing lever rises. Under

this condition the lower end of the tape-out sensing

lever does not interfere with the movement of its

associated tape-out operating lever and this lever, in

turn, is permitted to ride on its cam periphery. When it

drops into the cam indent, a pin on the tape-out

operating lever engages the tape-out contact lever, thus

rotating it about its pivot until at one end of the lever

the automatic contacts are opened, and on the other end,

the lever is latched by the tape-out contact lever latch.

This interruption of the clutch magnet circuit by the

opening of the automatic contacts stops the transmitter

unit and renders it inoperative.

- MANUALLY OPERATED TAPE-OUT CONTACTS -

The manually operated contacts are controlled by

depressing the release bar. The bar may be depressed

momentarily or it may be latched in the depressed

position with a slight forward pressure. Operation of the

release bar accomplishes three functions: opening of the

manual contacts to stop the transmitter, unlatching of

the tape-out contact lever thereby closing the tape-out

contact, and the disengaging of the feed wheel detent and

the feed pawl which permits the feed wheel to spin freely

to aid in the insertion or alignment of tape over the

feed pins. When the release bar is released the manual

contacts close and the transmitter operates.

The transmitter is equipped with a hinged tape lid

(figure 3) which permits the use of perforated or

chadless tape without altering its adjustments. Tape is

inserted directly under the latched lid after depressing

the release bar. For inserting tape loops, the lid may be

unlatched.

NUMBER TRANSMITTER (MXD-9)

The functions of the number and message transmitters are

identical with the exception of the letters sensing mechanism

which is a feature of the number transmitter.

Letters Sensing Mechanism

The letters sensing mechanism is used to stop the number

transmitter and to start one of the message transmitters when the

letters combination is sensed in the tape.

During every operating cycle, when the selector lever pins are

sensing the code combination in the tape, a letters operating

lever senses the ends of the five selector levers. If one or more

selector levers are in the spacing position, the letters

operating lever is prevented from continuing its travel. If the

code combination is letters (all marking impulses), the letters

operating lever is not blocked by any of the selector levers and

therefore is rotated through a larger angle. The letters

operating lever has two extensions, one of which rides on a cam

and permits the letters operating lever to sense the selector

levers, while the other engages the tape-out contact lever when a

letters combination is sensed in the tape and consequently opens

the tape-out contacts. These contacts are opened momentarily

since the tape-out contact lever is disabled in the number

transmitter. The momentary opening of these contacts causes the

number transmitter to stop and starts one of the message

transmitters by means of an external electrical control circuit.

MULTIPLE TRANSMITTER DISTRIBUTOR BASE (MXB-8)

The multiple transmitter distributor base has facilities for

mounting a motor unit and three transmitter units. The number

transmitter is mounted on the left side and the two message

transmitters are in the middle and right sides. A series governed

motor is used for operation on 115 volts D.C. or AC., 50 or 60

cycles. The motor is demountable as a complete unit and is

equipped with a governor filter.

The motor power is transmitted to the individual units through a

cross shaft. Each transmitter unit has an individual terminal

strip to facilitate disconnecting the transmitter cable to remove

the units. Underneath the base are the governor circuit elements,

a terminal block for external power connections and three sets of

spark protectors for the automatic and manual contacts on the

three transmitter units. A two-conductor power cord and an

eight-conductor cable, which terminates in plugs, provide

facilities for external connections.

A complement of covers provides dust protection. Although the

various sections of the covers are removable, a lid is provided

in the motor cover which may readily be opened to provide a view

of the speed target and access to the speed adjusting members. A

guard is provide on e cover in front of the number transmitter

through which the number tape will pass and be protected from

damage from external sources. A tape chute is provided to direct

the used tape from the unit on the right.

The front of the base is equipped with a card holder.

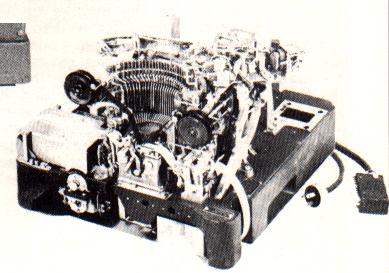

Another version, which incorporates a typing reperforator, is the

FRXD series. Several versions of these units have shown up

recently. A brief description is given. See Figure 3.

Reperforator Transmitter Distributor (FRXD)

General

- The Reperforator Transmitter Distributor is a motor

driven mechanism which combines in a single unit the

functions of a typing reperforator and a tape transmitter

distributor.

- The unit provides a fully automatic mechanism in which

the perforated tape may be stored in the form of a loop

to accommodate any delay in transmission, or in which all

the combinations in the tape up to and including the last

character perforated may be immediately transmitted. This

is accomplished by means of a pivoted tape transmitter

which moves along the tape, as it becomes taut, until it

reaches a position one character space (.100") away

from the point at which code perforation takes place.

Standard 11/16" wide perforator tape is used.

- The FRXD9 and FRXD1O reperforator transmitter

distributors have the same mechanical features with the

exception of the pull-bar-operated switching contacts

which are provided on the FRXD9 only.

- The reperforator transmitter distributor receives an d

retransmits signal combinations of the start-stop

five-unit code. This code utilizes five selecting

elements in combinations of current and no-current

intervals to form thirty-two code combinations. In order

to maintain synchronism between transmitting and

receiving units, each group of five selecting intervals

is preceded by a START interval and followed by a STOP

interval. Intervals during which current is transmitted

are designated as MARKING intervals and those during

which no current is transmitted are designated as SPACING

intervals.

Typing and Reperforating Mechanism General

- A method of tape perforating known as chadless

perforating is used to permit both printed and perforated

characters to occupy the same portion of the tape. The

punchings, or chads, are not completely severed from the

tape but remain attached to it at their leading edges so

as to form lids over the holes. The printed characters

are legible because the perforating does not eliminate

any portion of the tape.

- Typing and perforating occur simultaneously, but due to

the fact that the platen is to the right of the

perforator die block, characters are typed at the right

of their respective perforations. The separation between

the printed character and its associated perforation is

six character spaces. This separation must be taken into

account when tearing message tapes from the unit or in

cutting the tape. When the tape is to be used for

transmission by means of an external transmitter

distributor, the end of the tape should include all of

the printed characters in the message and the first

printed character of the message must be preceded by at

least six sets of code perforations in order to transmit

the entire message.

- When a message tape is inserted in the tape guide of an

external transmitter distributor, and the printed symbol

of the character to be transmitted is positioned opposite

the tape locating mark impressed in the tape guide, the

code perforation for that character will be over the tape

sensing pins in position for transmission. Under this

condition, if the tape retainer of the transmitter

distributor is fastened over the tape, the tape locating

mark will be covered, but the printed character will be

visible immediately to the right of the tape retainer.

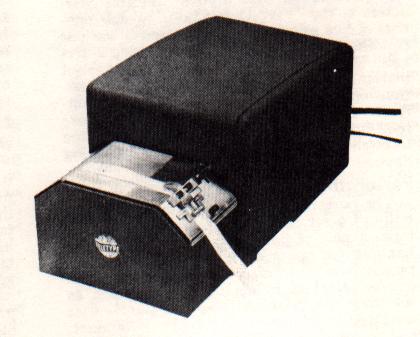

Later models of the TD series used with Model 28 equipments

are shown in Figs. 4 and 5. Single and dual versions are

available for such operations.

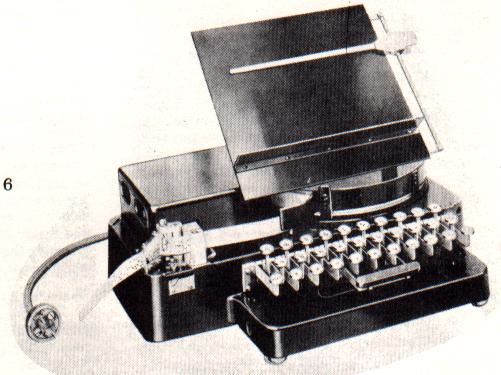

Several manual tape perforators are available, one

such unit is the Model 14. Fig 6. A DC supply is required to

operate the punch magnets, and "end of line" indicator

lamp. Several manual tape perforators are available, one

such unit is the Model 14. Fig 6. A DC supply is required to

operate the punch magnets, and "end of line" indicator

lamp.

DESCRIPTION OF THE FIVE-UNIT TAPE PERFORATOR Model 14

The Five-Unit Tape Perforator is a unit of apparatus that is

used to prepare perforated tape for automatic telegraph

transmission. Combinations of holes are perforated in the tape,

which correspond to the key lever depressed. The perforator tape

with the code combinations thus recorded may be fed automatically

through a tape transmitting device, operating a printer unit at a

distant point.

The Five-Unit Tape Perforator is a self contained magnet

(solenoid type) operated, portable unit. It consists essentially

of a set of keys and key levers; perforating, tape feeding, and

end-of-line indicating mechanisms. The unit is equipped with a

power cord and attachment plug for making connections to a source

of direct current power supply.

Signaling Code

The signaling code used to transmit characters is the

"Five-Unit Code," which consists of five selecting

impulses used in various combinations of spacing and marking

intervals. The large holes in the tape represent marking

impulses, whereas the impulse positions on the tape that are not

perforated represent spacing impulses. The small holes are feed

holes, which are used to feed the tape through the perforator and

the transmitting device.

Perforating Mechanism

The perforating mechanism consists essentially of a set

of punches for perforating the tape; a pair of punch magnets and

a punch hammer for operating the punches; a set of punch bars and

bell cranks; and loops and combs attached to each key lever used

in selecting the punches. The five punch bars are fitted in guide

slots in the punch hammer, just behind the punches and in line

with them. The right end of each punch bar is attached to a bell

crank and the opposite end of each bell crank engages a notch in

a loop extension. Each character or function key lever has a comb

with notches arranged so that its particular code combination

will be selected and perforated. The combs are cut out in such a

manner that the depression of a key will cause the comb to strike

the top edge of one or several of the loops, moving them

downward.

In addition to the five loops controlling the five punch bars,

there is a sixth or power loop which is operated by the

depression of any key. The downward movement of this loop closes

the punch contacts, energizing the punch magnet, and thus

operating the punch hammer.

The depression of a loop causes the punch bar connected to it to

be moved away from a punch so that when the punch hammer is

operated by the magnet, the tape will not be perforated at this

position; hut when a loop is not depressed, the punch bar

connected to it will be allowed to remain in the path of a punch

and a hole will be perforated. A feed hole is perforated with

each forward movement of the punch hammer.

For instance, if the "K" key lever is depressed,

only the #5 punch bar will be moved away from its punch. All the

other punch bars, however, will be driven against their punches,

causing the first four impulses to be perforated in the tape.

Tape Feeding Mechanism

The tape feed roll is located to the left of the

punches. Spaced at equal intervals around the tape feed roll is a

series of projecting feed pins which mesh with the feed holes

punched in the tape. A tape tension lever holds the tape against

the tape feed roll, keeping the feed holes in the tape in

constant mesh with the tape feed roll pins.

During the forward movement of the punch hammer, the tape feed

pawl, which is attached to the punch hammer, engages a tooth on

the tape feed roll. When the punch hammer moves back, the tape

feed roll will revolve, advancing the tape one character space. A

star wheel affixed to the lower end of the feed roll and a detent

insure equal spacing of the tape.

End-of-Line Indicating Mechanism (Nonadjustable)

The end-of-line indicating mechanism is intended for use

in connection with page printer reception. When sixty-four or

sixty-five combinations have been perforated in the tape, a red

lamp, under the keyboard, is lighted by the closing of contacts.

These contacts are closed by the action of the indicator gear.

This gear meshes, through an idler gear mounted on a lever, with

the tape feed roll pinion on the tape feed roll. Whenever the

tape feed roll moves the tape forward one space, the indicator

gear is advanced one tooth.

Mounted on the indicator gear is a pin "A". When the

indicator gear is advanced sixty-four or sixty-five teeth from

its starting position, pin "A" will move the lamp

contact ever so that its contact spring will touch the lamp

contact screw, lighting the lamp.

The advancing of the indicator gear winds up an indicator

return spring, one end of which is attached to the indicator

gear. When the operator depresses the "Carriage Return"

key, the key lever strikes a bell crank which moves the release

rod to the left. This throws the indicator idler gear out of mesh

with the tape feed roll pinion and the indicator gear is returned

to its starting position by the indicator return spring.

Since the "Carriage Return" key may not be held

depressed long enough to allow the indicator gear to completely

return to its starting position, a release rod holding pawl is

provided to insure that the gears stay out of mesh while the

indicator gear is returning. This holding p awl moves into a

notch in the release rod when the release rod is in its left-hand

position. When the indicator gear is almost returned to its

starting position, pin "B" (on the indicator gear)

moves the holding pawl out of the notch in the release rod and

permits the gears to again mesh.

End-of-Line Indicating Mechanism (Adjustable)

The adjustable end-of-line indicating mechanism is

similar to the non-adjustable end-of-line indicating mechanism

described in the foregoing.

The adjustable end-of-line indicating mechanism has an

adjustable stop plate mounted on the indicator gear. A

projection, extending downward from this stop plate, is used

instead of pin "B" to move the release rod holding pawl

out of the notch in the release rod.

The adjustable stop plate moves the release rod holding pawl

against an adjustable stop screw which determines the stop

position of the indicator gear. The adjustable stop plate may be

positioned so that the lamp contacts close on any operation from

the sixty-fourth to the seventieth.

Backspace Lever

A backspace lever is provided for moving the tape

backwards for the correction of errors. When the backspace lever

is being moved from left to right, it engages a pin projecting

from the tape feed pawl and cams the tape feed pawl out of

engagement with the tape feed roll ratchet. Toward the end of the

travel of the backspace lever, the backspace pawl (which is

mounted on the backspace lever) engages a tooth of the star

wheel, rotating it backwards one space. The "Letters"

key may then be depressed, causing five holes to be perforated

over the previous perforation. This combination may be passed

through the tape transmitting device without causing any

character or letter to be printed on the receiving printer.

However, if a character in the upper case is corrected, it will

be necessary to strike the shift key (Figures) again, because the

"Letters" combination will unshift the receiving

printer.

Repeat Mechanism

The repeat mechanism provides a means of continually

perforating a desired code combination in the tape. With any key

lever and the repeat push button simultaneously held depressed,

the code combination corresponding to the key lever depressed

will continue to be perforated until the repeat push button is

released.

When any key lever is held depressed, the punch magnet circuit

is completed through the punch magnet contacts. The operation of

the punch magnet permits the magnet yoke contacts to close,

completing a circuit through the winding of the repeat relay if

the repeat push button is depressed. The operation of the repeat

relay breaks the punch magnet circuit. The punch magnet yoke is

released, opening its contacts, which open the repeat relay

circuit. The repeat relay releases its armature, closing the

punch magnet circuit, thus setting up a repeated cycle of

operation. Repeat action will continue as long as any key lever

and the repeat push button are simultaneously held depressed.

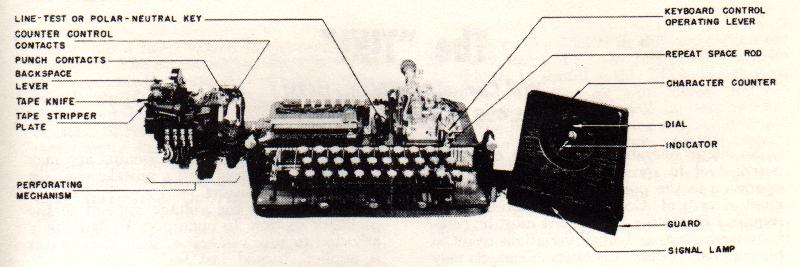

Another manual tape perforator is the Model 15 perforator

transmitter, keyboard, which is used on the Model 19 set. Fig. 7.

It also requires an external DC supply to operate the punch

magnets.

General

The Model 15 perforator transmitter is a combination

transmitter and perforator with an electrically operated

character counter. It is inserted in the base of a Model 15

printer when the Model 15 printer is used in conjunction with a

Model 19 table and a Model 14 transmitter distributor. When this

combination of units is used together, it is known as a Model 19

printer set.

The perforator transmitter is furnished with the character

counter mounted either to the left or to the right of the unit.

When the counter is mounted to the right of the unit, a separate

cover is provided for it. When mounted to the left of the unit,

the counter is covered by an extension of the printer cover.

A manually operated, three position keyboard control operating

lever is mounted at the right-hand end of the unit. The selection

of any one of the four methods of operation may be made by

placing this operating lever and the line test key in one of the

following positions:

- OPERATING LEVER IN UPPER OR "KEYBOARD"

POSITION

Direct keyboard transmission to the line with a

printed record being produced at the transmitting point.

The maximum speed of the keyboard is limited to the

predetermined speed of the set.

- OPERATING LEVER IN MIDDLE OR "KEYBOARD AND

TAPE" POSITION

Simultaneous direct keyboard transmission to the

line and perforation of tape with a printed record being

produced at the transmitting point. The maximum speed of

the keyboard is limited to the predetermined speed of the

set.

- OPERATING LEVER IN LOWER OR "TAPE"

POSITION -Perforation of tape only, with the

associated printer either reciving messages from a

distant station, or monitoring the message perforated in

the tape as it is being transmitted to the line by a

transmitter distributor.

The character counter registers each time a character or

space key is depressed and returns to its zero position

when the "Carriage Return key is depressed.

Operation of the "Letters,"

"Figures," or "Line Feed" key levers

does not cause the character counter to register. The

counter is provided with a signal lamp to indicate when

the end of a line is being approached. The maximum speed

of the keyboard in this case is not limited to the

predetermined speed of the set and the operator may,

therefore, perforate tape at speeds much higher than the

speed at which a tape transmitter would send to the line.

- OPERATING LEVER IN MIDDLE OR "KEYBOARD AND

TAPE" POSITlON AND SET CONNECTED FOR LOCAL OPERATION

- It is also possible to perforate tape and print a home

record without transmitting directly to the line when the

set is connected for local operation. This method is

helpful in preparing perforated tape for use in

connection with printed forms. The maximum speed of the

keyboard is limited to the predetermined speed of the

set.

Signaling Code

The signaling code used to transmit characters is the

"Start-stop" five-unit code, which consists of five

selecting impulses used in various combinations of current and

nocurrent intervals. Each group of five selecting impulses is

preceded by a start impulse and followed by a stop impulse, which

are used to maintain synchronism between stations on the circuit.

Impulses which energize the selector magnets on the printer are

known as marking, and those which do not are known as spacing.

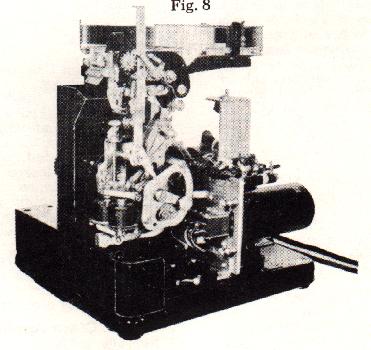

The Model 14 Typing reperforator is shown in Fig. 8. This is

by far the typing reperf to be found in most amateur RTTY

stations who have tape equipment. Several of the typing reperf

units only, less base and cover, have been listed in the Horse

Trades section of RTTY in the past. Both type of selectors magnet

assemblies are found on these units. Hence, provision for either

20 or 60 mils can be had on the units with the holding type of

selectors, and some have the series or parallel switch which is

found mounted behind the selector unit. Some also have an

"end of line indicator" assembly which operates a lamp

after 72 or what ever number of characters it has been set for,

has been perforated. The unit shown has a keyboard, but many 14

typing reperfs have been issued by MARS which are receiving only,

in other words, no keyboard.

Another version of the 14 reperforator is shown in Fig. 9

which is called "Single Magnet Reperforator". It also

is made in a six level tape version, which has been used on the

TELETYPESETTER, in news service.

DESCRIPTION OF THE SINGLE MAGNET REPERFORATOR 14 AND 20 TYPE

There are two types of Teletype single magnet reperforators;

the 20 type, which operates on the six-unit code and the 14 type

which operates on the five-unit code. This bulletin mainly covers

the 20 type six unit reperforator. However, the mechanical parts

of the 14 type reperforator are the same as the 20 type except

the parts associated with the zero pulse are not used, such as

the zero selector lever, sword, "T" lever, transfer

lever, and punch lever. Also, different range scales, punch

blocks, selector cams, feed rolls and guides are used on the five

unit reperforators.

The Teletype reperforators are motor driven tape reperforating

machines which receive electrically transmitted signals and

translate these signals, through the medium of selecting and

perforating mechanism into code combinations of holes in a paper

tape. This tape may then be used for retransmitting these code

combinations on other similar printing telegraph circuits; thus

eliminating manual preparation of tape with a perforator at the

relaying station.

Signaling Code

The signaling code used for the 20 type single magnet

reperforator is a six unit start-stop code which consists of six

selecting impulses used in various combinations of current and

no-current intervals. Each group of six selecting impulses is

preceded by a start impulse and followed by a stop impulse to

maintain unison between the sending and receiving apparatus.

Impulses which operate the selector magnets are known as marking

and those which do not operate the selector magnets are known as

spacing. Figure 1 shows graphically the six unit code.

The signaling code used for the 14 type single magnet

reperforator is the same as the six unit code except that the

zero impulse is omitted.

RTTY is indebted to the TELETYPE CORPORATION for permission to

reprint portions of this material. Their current equipment is

being widely used for TWX service (MTWX) and also in association

with many computers. An example of such advanced equipment is the

Model 33 ASR which was shown on the cover of the July 1963 RTTY.

If your non-hobby needs are for such equipments, write to them

at:

TELETYPE CORPORATION

5555 Touhy Avenue

Skokie, Illinois

|